Custom Shaft Machining: Creating the Components That Make Industry Turn

Share

Introduction to Custom Shaft Machining

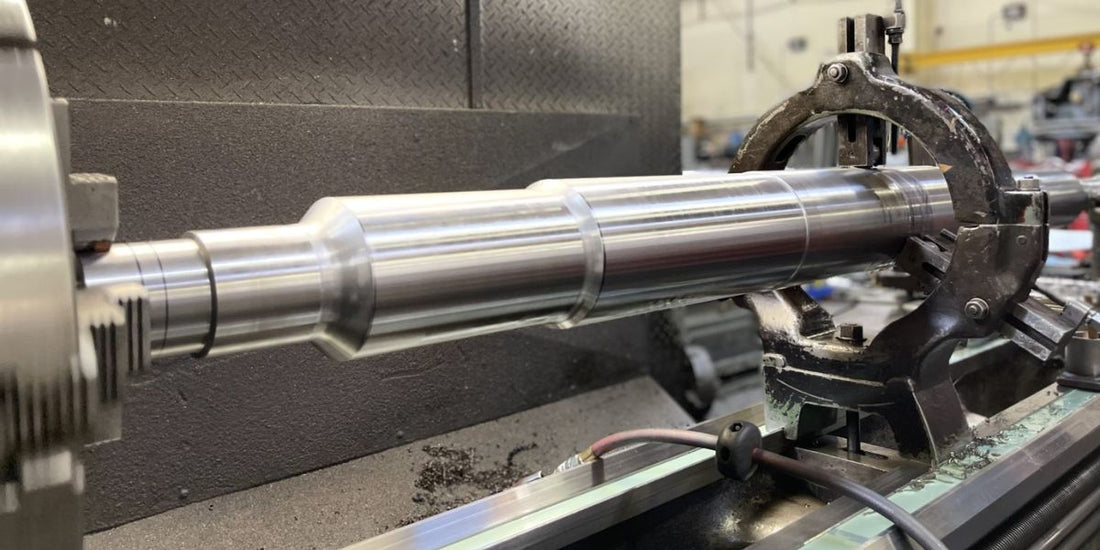

The first time I watched a shaft being machined, I was shocked by how much work goes into something so seemingly simple. Looks can be deceiving. That plain metal cylinder might not catch your eye, but without precisely machined shafts, most machines around us would grind to a halt.

Last month a customer brought in a failed gearbox from his production line - £15,000 of damage because someone had installed a shaft that was 0.1mm out of true. A tenth of a millimeter! You can't even see that with the naked eye.

We've been doing custom shaft machining since we opened our doors at Brightstone Engineering. Each shaft presents its own challenges. Steel shafts make up most of our work - they're strong and relatively cheap - but we also machine plenty of stainless when corrosion is a concern. One food processing company we work with switched all their shafts to stainless after a costly contamination incident. Materials matter.

A brewery customer tried saving money with cheaper shafts in their filling line and ended up spending £8,000 on emergency repairs three months later. In the following sections, I'll share what we've learned about the critical aspects of shaft production - not just the textbook stuff, but the real-world lessons that come from seeing what works and what fails when these components get put to the test in actual machines running day and night.

At our shop, Brightstone Engineering, custom shaft machining represents a significant portion of our work. We can machine shafts up to 300mm diameter and 760mm in length on our Warco GH1230 lathe - handling most industrial requirements our customers bring through the door. Plus, with our 3D scanning capabilities, we can reverse engineer existing shafts when drawings aren't available.

Types of Custom Shafts

Walk through any factory and you'll find dozens of different shaft designs, each shaped for a specific purpose. The simplest are straight shafts - uniform cylinders that might carry pulleys or gears. We machine these from 5mm diameter up to 300mm on our manual and CNC equipment, depending on the load they'll bear.

Then you've got stepped shafts with multiple diameters along their length, often used where components need to be positioned precisely. These require careful planning and multiple setups to achieve the required tolerances. The precision affects the price; a complex stepped shaft in stainless steel might cost £350-500 compared to £75 for a simple straight version.

Splined shafts feature ridges or teeth that mesh with matching holes in gears or pulleys, transferring torque without keys or set screws. These require more complex machining operations, often combining work on our manual mill with finishing on the CNC.

We recently completed a batch of custom splined shafts for an agricultural equipment manufacturer, each one requiring multiple setups between our lathe and milling machines. Keyed shafts offer another solution for torque transfer, with slots cut to accept rectangular keys - something our Warco Major Mill handles well.

Then there are threaded shafts, tapered shafts, hollow shafts - each serving specific needs in various machines. The type you choose depends on several factors: load requirements, speed of rotation, operating environment, and cost constraints. I've seen customers save £2,000 on a project by letting us suggest a simpler shaft design that still met their performance needs.

Materials Used in Shaft Machining

Material selection makes or breaks a shaft's performance in the field. Carbon steel remains the most common choice for our custom shaft machining work because it offers good strength at a reasonable price - about £4-6 per kilogram compared to £12-15 for stainless.

We use it for everything from simple motor shafts to heavy-duty drive components. But carbon steel rusts, which is why stainless steel shafts dominate in food processing, medical equipment, and outdoor applications. Last year we machined a batch of 316 stainless shafts for a customer's marine equipment - they cost twice as much as carbon steel but didn't corrode even after months of exposure.

Aluminum shafts serve where weight matters more than ultimate strength. They're roughly one-third the weight of steel and much easier to machine, which can reduce production costs despite the higher material price. We recently produced aluminum shafts for a motorsport application where every gram counted.

For truly demanding applications, we work with specialized alloy steel containing chromium, nickel, or molybdenum. These materials cost more (sometimes £20-25 per kilogram) but deliver exceptional properties. One customer's high-speed machinery needed shafts that could withstand continuous operation at high RPM - only a special alloy provided the fatigue resistance needed.

The material choice depends on your specific requirements: operating temperature, load characteristics, environmental conditions, and budget constraints. Get it wrong, and even the most precisely machined shaft will fail prematurely. I've seen £5 saved on materials turn into £5,000 in downtime and repairs.

Machining Processes Explained

Shaft machining starts with turning - the fundamental process where the workpiece rotates against a cutting tool. Our Warco GH1230 manual lathe handles much of our custom shaft machining work, with the operator's skill making the difference between good parts and great ones. For production runs or complex profiles, our Haas TM1P CNC milling machine takes over, holding consistent tolerances across multiple parts.

The difference between basic shaft machining and precision shaft machining comes down to both equipment capabilities and operator experience. After years of machining, you learn to detect problems by sound and feel that measuring tools might miss.

Beyond turning, many shafts require additional operations. Our Warco Major Mill creates keyways, slots, and other features that simple turning can't achieve. One mining equipment shaft we produce requires multiple precisely positioned holes and two keyways - a perfect example of combining turning with milling operations.

When customers bring us damaged shafts without drawings, our Shining 3D Einstar handheld scanner captures the geometry digitally, allowing us to machine exact replacements or even improve on the original design.

The shaft manufacturing processes we select depend entirely on the application requirements and specified tolerances. For some agricultural shafts, basic turning meets the need at the lowest cost. For precision components, we might employ multiple machining operations across our different machines. Process selection affects both price and delivery time - a simple turned shaft might cost £65 and take two days, while a complex shaft requiring multiple operations could run £350 and need two weeks to complete.

Surface Finishing Options

A precisely machined shaft is only part of the equation. The surface finish often determines how a shaft performs in service. After shaft machining is complete on our equipment, we can typically achieve good surface finishes that reduce friction and wear on mating components.

Beyond basic finishing, we offer surface treatments that significantly improve shaft performance. Our anodizing capability handles aluminum shafts up to 400mm square, creating a hard oxide layer that protects against corrosion while adding color for identification. This process adds modest cost (typically £25-45 per shaft depending on size) but dramatically improves service life.

For steel shafts requiring enhanced wear resistance and appearance, we offer cerakoting - a ceramic-polymer coating that provides excellent durability and comes in various colors. Like our anodizing, this covers parts up to 400mm square and costs around £35-65 per shaft depending on complexity.

We recently cerakoted a batch of custom drive shafts for an off-road vehicle manufacturer. The coating not only protected against corrosion but gave them the distinctive appearance they wanted for their premium product line.

Before any finishing process, parts go through our blasting cabinet to clean and prepare surfaces. This step removes machining marks and creates the proper surface texture for coatings to adhere properly.

The shaft finishing techniques we recommend depend on operating conditions, mating components, and expected service life. A shaft running in a clean, lubricated environment might need minimal finishing, while those exposed to harsh conditions require additional protection. Custom shaft machining is only as good as its finishing - even precision-machined components will fail prematurely if the surface treatment doesn't match the application.

Design and Precision in Machining

Shaft design often determines whether a machine runs for years or fails in months. I've seen dozens of premature failures caused by poor design choices rather than machining issues. Stress concentration points, inadequate fillets at diameter transitions, and incorrect specifications account for most problems.

We now review every custom shaft design that comes through our door, often suggesting subtle changes that dramatically improve performance. Last year, adding a 2mm radius where a customer had specified a sharp corner extended the service life of their conveyor shafts from 8 months to over 2 years - a £4,500 annual saving in replacement costs alone.

Precision in shaft machining has improved dramatically with our combination of manual skill and CNC capability. On our manual equipment, we consistently hold ±0.025mm tolerances, while our Haas CNC can achieve ±0.01mm for critical features. This precision matters tremendously in high-speed applications where even minor imbalance causes vibration and bearing damage.

When customers don't have drawings, our 3D scanner captures existing shafts with incredible accuracy, allowing us to machine exact replacements or identify areas for improvement. One customer brought us a worn pump shaft from a discontinued machine - we scanned it, machined a replacement, and actually improved the bearing journal finish in the process.

For complex shafts with multiple features, we plan the machining sequence carefully to maintain accuracy while minimizing setups. One challenging project required seven different diameter transitions with tight tolerances - we developed a sequence using both our manual and CNC equipment that delivered parts within specification every time.

Quality Control and Inspection

Quality control isn't just a final step in our shaft machining process - it's built into every operation. Every shaft goes through inspection using precision measuring tools including micrometers, calipers, and dial indicators accurate to 0.01mm or better.

We maintain detailed records for critical components, documenting key dimensions and any special requirements. One automotive customer requires specific documentation for transmission shafts we produce - these inspection records protect both us and our customers if questions arise later.

The shaft inspection methods we employ depend on both the material and the application. For precision shafts, we check multiple points along the length to verify straightness and diameter consistency. Our manual equipment allows us to take measurements during machining, catching potential issues before they become scrap.

We recently machined a batch of 50 drive shafts where the tolerances were critical for proper bearing fit. By checking each shaft at multiple stages during production, we delivered all 50 parts within specification on the first attempt.

Surface finish verification is equally important, especially for shafts that will receive our anodizing or cerakoting treatments. The base finish affects how well coatings adhere and their final appearance.

All our measuring equipment receives regular calibration and maintenance. While we don't have the overhead of larger shops, we take accuracy seriously because the most expensive shaft is the one that fails after installation - often causing ten times its value in downtime and collateral damage.

Choosing the Right Shaft Manufacturer

Selecting a partner for custom shaft machining involves more than finding the lowest quote. I've seen companies save £200 on a batch of shafts only to spend £5,000 on emergency repairs when those parts failed prematurely.

Start by examining potential suppliers' equipment capabilities - not all shaft machining services are equally equipped. At Brightstone Engineering, our combination of manual and CNC machining gives us flexibility that purely automated shops sometimes lack. We can handle shafts up to 300mm diameter and 760mm length, covering most industrial requirements while maintaining competitive pricing.

Ask about their typical tolerances and what inspection documentation they provide. We supply detailed measurements for critical dimensions and maintain records for future reference. When you need replacement parts years later, having those specifications saves time and money.

Experience with your specific requirements matters tremendously. A manufacturer might be excellent at general machining but unfamiliar with your application. When we quote new customers, we often show them comparable shafts we've machined for similar applications.

Our 3D scanning capability sets us apart when you need to replicate existing shafts without drawings. Many shops can't offer this service, forcing you to reverse-engineer parts manually or create drawings from worn components.

Turnaround time matters but be suspicious of quotes promising extremely quick delivery for complex work. Quality custom shaft machining takes time, especially for tight-tolerance parts. We typically quote 3-7 working days for standard shafts and 1-2 weeks for complex components requiring multiple operations.

Most importantly, look for a supplier who takes time to understand your application. The best shaft is one designed specifically for your needs, not just copied from existing parts. At Brightstone Engineering, we view every project as a partnership - your success is our success.

Industry Applications of Custom Shafts

Custom machined shafts form the backbone of countless industries, each with unique requirements. In automotive applications, precision shaft machining creates transmission components and drive shafts that must withstand varying loads and speeds.

We recently produced a batch of custom input shafts for a performance gearbox - machined from high-strength steel and finished with our cerakoting process for both protection and appearance. At £185 per shaft, they represented significant value for a specialized application where standard parts weren't available.

Marine applications present different challenges, with corrosion resistance being paramount. We machine propeller shafts and steering components from stainless steel that costs more initially but provides years of reliable service in saltwater environments.

One boat builder switched to our custom shafts after suffering repeated failures with standard alternatives. The initial investment saved them thousands in warranty repairs and customer complaints.

Industrial applications often require shafts that standard suppliers can't provide. We've machined everything from conveyor drive shafts to pump components, often working from customer sketches or damaged parts that we scan and improve.

Food processing equipment demands both precision and cleanliness - we machine these components from stainless steel with appropriate surface finishes, then apply our anodizing or specialized coatings as needed.

Agricultural machinery presents unique challenges with seasonal loading and outdoor exposure. Our combination of proper material selection and protective finishing helps these shafts survive harsh conditions year after year.

From small motor shafts to heavy-duty industrial components, custom shaft machining at Brightstone Engineering delivers parts tailored to specific operational demands. Our capacity to handle shafts up to 300mm diameter and 760mm length, combined with our finishing capabilities, means we can solve problems that standard suppliers can't address.

Whether you need precision automotive components or robust industrial shafts, our combination of manual expertise, CNC capability, and specialized finishing processes delivers solutions that work in the real world.